Plastic Injection molding screw barrel

Design: The injection screw barrel typically consists of a screw and a cylindrical barrel. The screw is a helical-shaped component that fits inside the barrel. The screw's design may vary depending on the specific application and the type of plastic being processed.

Melting and Mixing: The primary function of the injection screw barrel is to melt and mix the plastic material. As the screw rotates within the barrel, it conveys the plastic pellets or granules forward while applying heat and shear. The heat from the barrel's heating elements and the friction generated by the rotating screw melt the plastic, creating a homogenous molten mass.

Injection: Once the plastic material is melted and homogenized, the screw retracts to create space for the molten plastic. Then, using the injection plunger or ram, the molten plastic is injected into the mold through the nozzle at the end of the barrel. The injection speed and pressure are carefully controlled to ensure proper filling of the mold cavities.

Materials and Coatings: Injection screw barrels are subjected to high temperatures, pressures, and abrasive wear during the injection molding process. Therefore, they are typically made of high-strength alloy steel to withstand these conditions. Some barrels may also feature specialized coatings or surface treatments, such as nitriding or bimetallic liners, to enhance their wear resistance and extend their lifespan.

Cooling: To prevent overheating and maintain consistent processing temperatures, injection screw barrels are equipped with cooling systems. These systems, such as cooling jackets or water channels, help regulate the temperature of the barrel during the injection molding process.

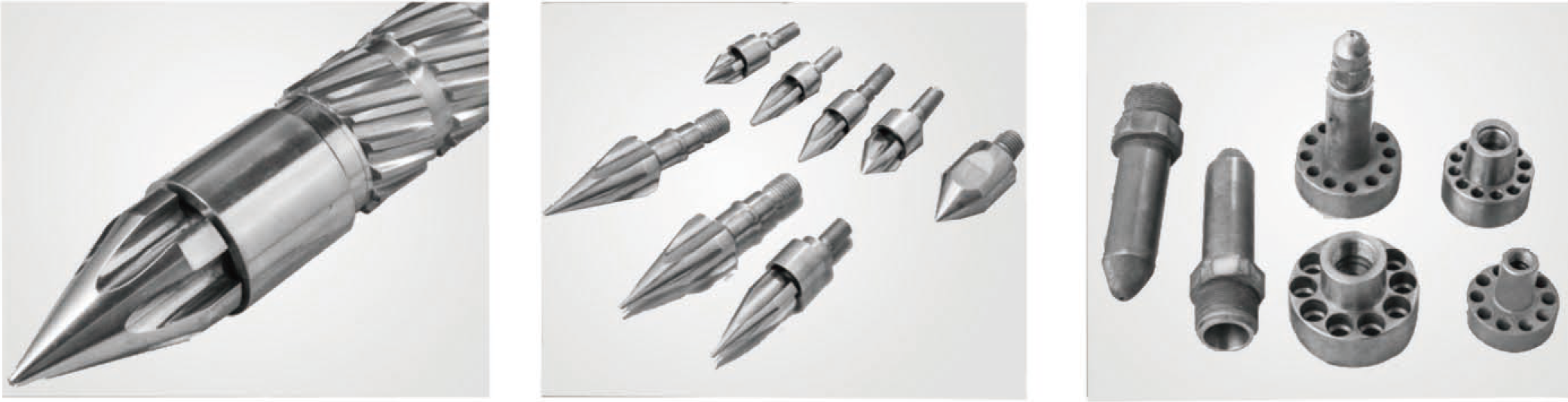

Screw Design and Geometry: The design of the injection screw, including its length, pitch, and channel depth, can vary based on the specific requirements of the plastic material being processed. Different screw designs, such as general-purpose, barrier, or mixing screws, are used to optimize the melting, mixing, and injection characteristics for different types of plastics.

Injection screw barrels play a critical role in the injection molding process, enabling the efficient melting, mixing, and injection of plastic materials into molds to produce a wide range of plastic products.